Kuala Lumpur City Centre: A Case Study by MEIKO

Kuala Lumpur’s City Centre is known for its upscale fashion malls, luxury hotels and fantastic views from the iconic Petronas Twin Towers. The Kuala Lumpur Convention Centre, Asia’s first AIPC (International Association of Congress Centres) Gold Standard venue is also located here.

A five-level purpose-built facility in the heart of Kuala Lumpur City Centre precinct, the Centre has over 33,000 sqM of facilities including two Auditoria; Plenary Hall and Plenary Theatre; a Grand Ballroom, Banquet Hall, three Conference Halls, Meeting Rooms and eight Exhibition Halls.

The Centre hosts local and international conferences, corporate events, exhibitions and competitions such as Food & Hotel Malaysia, Asia Water Expo and the International Invention, Innovation & Technology Exhibition Malaysia (ITEX). Achieving Gold Standard AIPC recognition involves winning top marks in key areas of convention centre performance, including Environmental Responsibility as well as Customer Service and Quality of Facilities and Operations.

One of Malaysia's largest kitchens

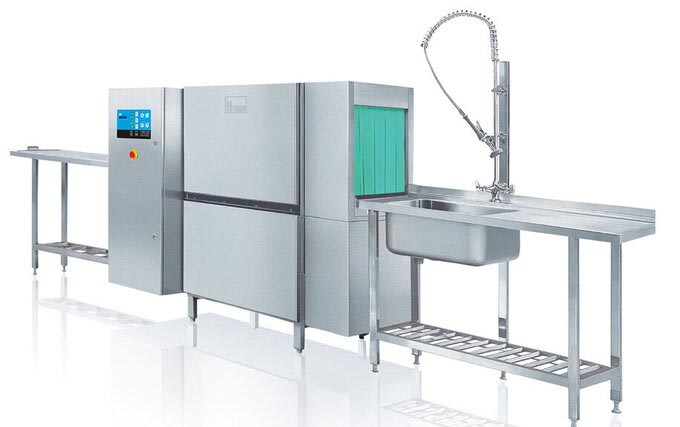

The Centre operates one of the largest commercial kitchens in Malaysia and has installed a range of MEIKO dishwashing equipment since 2015, including a FV250.2 pot washing machine,two M-iQ flight type dishwashers, a K200M rack transport dishwasher and a UPster U500 undercounter machine.

There are two main washing areas. The main washing area is for the Grand Ballroom and Banquet Hall on Level 3 which seat 2,000 and 500 diners respectively, where two M-iQ flight type dishwashers act as the backbone. These machines feature built in heat recovery and are dedicated to washing the bulk of crockery and buffet dishes. Compared to the previous generation machines, the M-iQ's deliver savings of 30 per cent in energy and chemicals.

The other main washing area is fully dedicated for the food court of the convention centre where there is the K200M which handles all the wares here.

Steam issues in the kitchen resolved

MEIKO offers complete dishwashing cleaning solutions and MEIKO South East Asia is proud of its record in both customer service and after sales support.

"The kitchen here is busy and operates for long hours, preparing and serving food to the highest standards. And support from MEIKO has always been there for us," says Executive Chef Hisham bin Jaafar.

He adds satisfactorily: "The previous dishwashing machine produced a lot of steam and sometimes the whole place was like a sauna. With the M-iQ Air Concept, we’re able to solve this issue. Now the working conditions are much better for our staff and we are very satisfied that we achieve consistent, hygienically clean washing results in a comfortable working environment.”

Maintenance and Labour

Head of Stewarding is Parameswaran a/l Marimuthu Pillay, who noted that the dishwashing equipment can be running continuously every day.

The workload includes tableware, glassware, flatware, cutlery, hollowware, utensils, as well as buffet ware and washable buffet props from the many functions that can take place.

Operational hours depend on events and it is not unusual for a busy session to run from 7 am to 1 am the following day.

As well as improvement in the wash and rinse results, water and energy consumption have been reduced.

With the previous dishwashing system, the wash water needed changing every two hours to achieve satisfactory results. With MEIKO's dishwashers less frequent changes of wash water are needed because of their highly efficient filtration. The M-iQ dishwashers, for example, continually flush food particles out of the wash tank during the washing process to ensure the cleanest possible wash water.

With improved washing results leading to a faster throughput compared to the old system, the amount of labour required has also reduced.

"Workers can accomplish more tasks as washing time has been shortened," says Parameswaran. "Less time in use and less frequent water changes results in a more environment friendly operation, with less water being refilled and reheated and so we are achieving both water and energy savings."

The wash and rinse filters are colour-coded blue, making it easier for staff to locate and remove them for regular cleaning. The colour coding and ease of access designed by MEIKO helps with food safety because it is easier to do maintenance in terms of cleaning.

Parameswaran also noted that the MEIKO machines are higher off the ground which improves access for cleaning and removal of soil beneath the machine as part of the regular maintenance process.

Of course, food safety and hygiene are top-priority and Parameswaran is in no doubt that MEIKO is contributing to a cleaner future: "With MEIKO, our operation is safer, because we now have a much better environment for working and it is easier to maintain the required hygiene standard."

Kuala Lumpur’s City Centre is known for its upscale fashion malls, luxury hotels and fantastic views from the iconic Petronas Twin Towers. The Kuala Lumpur Convention Centre, Asia’s first AIPC (International Association of Congress Centres) Gold Standard venue is also located here.

Kuala Lumpur’s City Centre is known for its upscale fashion malls, luxury hotels and fantastic views from the iconic Petronas Twin Towers. The Kuala Lumpur Convention Centre, Asia’s first AIPC (International Association of Congress Centres) Gold Standard venue is also located here.